【Improvement Case Study】Reduction in Mold Component Assembly Labour Hours

- SANKO GOSEI

- 2025年10月1日

- 読了時間: 3分

更新日:2025年12月18日

Introduction

In the field of injection molding in recent years, alongside the diversification of products and the trend towards high-cycle production, mold structures have also become increasingly complex. Among these developments, the increase in the number of blocks within ejector pin protrusion structures presents a significant challenge.

Block assembly work accounted for a significant portion of the man-hours in the finishing process, not only extending working time but also complicating personnel planning and schedule setting. This paper therefore introduces the initiative undertaken by Esbans Co., Ltd. to reduce part-fitting man-hours.

Background and Challenges

Block fitting is a manual process to ensure proper mating between blocks (protruding shapes) and main molds (recessed shapes). As machining alone yields insufficient precision, the finishing department employs rotary tools and files for fine adjustments to secure mating accuracy. However, the following challenges became apparent:

Increased finishing workload

The proportion within the overall process expanded due to the increased quantity of machined blocks.

Variability in working time

Significant differences in the time required to fit each individual block arose because the amount of material to be removed was not consistent.

Unstable process planning

Predicting lead times and personnel allocation became difficult, impacting the efficiency of the entire manufacturing operation.

As a result, assembly time accounted for 25% of the entire finishing process, becoming a bottleneck for efficiency improvements.

Pre-improvement situation

The investigation revealed the average processing time per component as follows:

Upper block: 40 minutes per unit

Inclined block: 120 minutes per unit

Core bushing: 60 minutes per unit

Furthermore, for polyhedral-shaped components, even when design tolerances were set, they tended not to fit well balanced, leading to increased machining allowances. In particular, the inclined block required extensive machining, posing a significant burden on the finishing operators.

▸Cross-section before improv

Direction of Improvement

The core of the improvement activities centred on **‘standardising optimal fit values and machining tolerances’**.

Initiatives Undertaken

Collection of Actual Measurement Data

Multiple molds were used to measure mating surfaces immediately after machining, analysing the clearance at the base and the mating angle.

Trial of Tolerance Conditions

Blocks machined to various tolerances were physically mated, with the machining time recorded.

Derivation of Optimal Values

Conditions were identified where the machining allowance was minimal and the operation could be completed in the shortest time.

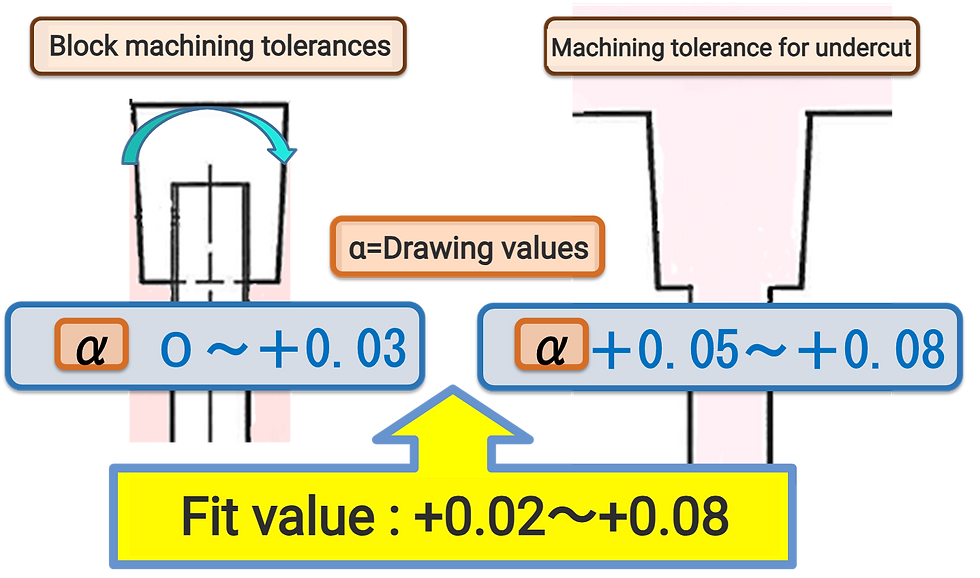

The standard values ultimately derived are as follows:

Block machining tolerance: 0 to +0.03

Recess machining tolerance: +0.05 to +0.08

Fitting tolerance: +0.02 to +0.08

This has established a system ensuring consistent quality and efficiency regardless of the operator.

Improvement Results

Standardisation has significantly reduced component assembly time.

Upright block: 40 minutes → 10 minutes (75% reduction)

Inclined block: 120 minutes → 45 minutes (62.5% reduction)

Core bushing: 60 minutes → 15 minutes (75% reduction)

Overall, we succeeded in reducing assembly man-hours by approximately 70%.

Furthermore, the following cost benefits were achieved:

Vertical Block: ¥344,000 → ¥86,000

Inclined Block: ¥206,000 → ¥77,000

Core Bush: ¥37,000 → ¥9,000

In total, a substantial reduction was realised, from approximately ¥589,000 to ¥173,000.

Ripple Effects of the Outcomes

The reduction in part-fitting man-hours yielded the following effects beyond mere time savings:

Enhanced Overall Process Efficiency

The proportion of die-sinking and polishing processes decreased, improving the balance of movable-side assembly.

Improved Planning Accuracy

Tolerance standardisation enabled pre-calculation of working time based on block count, enhancing the accuracy of personnel allocation and schedule planning.

Stabilisation of Quality

Reduced reliance on manual finishing led to lower variation in finished quality.

Future Developments

While this initiative targeted parts within 100mm square, future plans include:

Extension to Large Parts Over 150mm in Height

Verifying similar effects on more complex components.

Application to Cavity Slide Fitting

Aiming for further reduction in part-fitting man-hours.

Summary

This improvement case study demonstrated that by ‘identifying optimal mating values’ and ‘standardising machining tolerances’, we reduced part-fitting man-hours by 70%, positively impacting cost, quality, and process planning.

This achievement represents a successful example of typical QC improvement activities combining on-site expertise with data analysis, and will serve as an important guideline for future mold technology innovation

コメント